Experiments With an Oil Burner on a Small Boiler

I was very impressed with the oil burner in Dave Johnson’s 1” scale Pacific, which Dave told me was based on Dick Bagley’s design that was featured in Live Steam back in the 1980’s. I built one of these along with a suitable fire pan and test fired it on my boiler. Sure enough, I had a real soot factory going. I removed the fire pan and observed the operation in the open. The burner operated okay when everything was pre-heated, but the flame was about 18” long, which is much longer than the boiler tubes. When installed in the boiler, the ignited gasses were undoubtedly cooling below the flash point in the tubes, thus creating soot from incomplete combustion.

I have a backpacking stove that operates on kerosene, which has a very hot, short flame during operation. The stove’s secret is a preheating coil sitting in the flame which vaporizes and superheats the fuel close to the flash point before going through the regulating valve and nozzle. I was convinced that similar preheating would solve my problem. I set about to make a pre-heater coil out of mild steel brake line with 4 turns sitting in the flame path. A regulating valve was placed outside the fire pan between the coil and the burner.

This arrangement yielded a very satisfactory flame, short and hot. But the burner wouldn’t stay lit. I realized that the pre-heater coil was building up back pressure which prevented liquid fuel from getting to the coil. Closer inspection of the backpack stove reveals that a braided steel cable is threaded through the pre-heater coil; this serves as a wick. Also, the fuel tank has a small pump to maintain pressurization. I inserted some 1/16” diameter cable into my coils and hooked the stove fuel tank up as my fuel supply.

Problem solved! The burner stays lit with a satisfactory roar. Installed on my boiler, the burner heated the water rapidly and was up to operating pressure in about 15 minutes, with no smoke or soot. Since the boiler was not mounted on my locomotive, I had to apply a little blower to maintain proper draft. Throttling back the burner to an idle flame proved a little tricky at first, requiring some coordination of blower and atomizer controls, but it did simmer nicely. However, the atomizer was being fed with air at this time, not steam, so it was contributing to the combustion.

This experiment revealed a couple of minor problems with the setup. First, the system seems to require a pressurized fuel tank. I don’t regard this as a bad thing, as this can help any burner perform better and reduce the number of refueling stops. The other problem was that the needle valve regulating fuel to the burner gets very hot from the superheated fuel vapor traveling through it. So hot that it burned out the Teflon valve stem packing in the Superscale globe valve I was using, and annealed the brass components. Putting the valve before the pre heater resulted in poor control over the flame. I managed to cauterize my fingers when I carelessly grasped the valve wheel without gloves. I substituted graphite glass wool for packing the stem; this seems to work okay. I later built a new regulator, it is a 90-degree cock valve that I built especially for the burner, using a stainless steel core. It doesn't completely shut off the flame, as enough fuel vapor seeps through it to keep the burner lit anyway. It does do a good job of throttling the flame though, and allows for a prototypical control handle in the cab, with a stem long enough to keep the handle from getting hot.

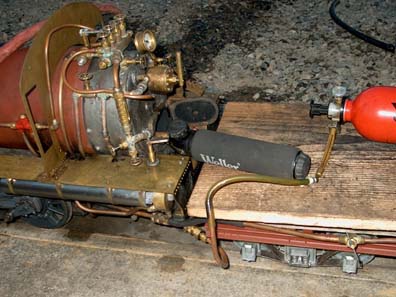

Partly completed SP S-9 rigged for test firing

When I had the locomotive completed to the point that I could operate it under steam I got better acquainted with the burner. The first thing I ( and everyone else ) noticed was that the burner was starved for air. Flames would flash towards the roadbed out the draft opening, and areas around the burner upstream of the draft opening collected carbon deposits. I solved this by drilling a couple rows of 5/32" holes around the perimeter of the fire pan, much like a pot burner would have. I drilled a few extra holes around the burner itself for good measure.

The next thing I found was the importance of preheating the burner and

pre-heater coils with a propane torch for a few minutes prior to lighting

off. If this is not done, raw liquid fuel will come out of the burner

in quantity, forming a burning pool under the engine. If the burner

is properly preheated then light-off can be accomplished with little mess

and waste of fuel.

I was unsure of what role the atomizer line would play when the fuel

was already vaporized. In my earlier run trials, the steam orifice

somehow got clogged, but the burner seemed to work satisfactorily without

it, I just needed to crank the blower. I ran the engine for some

time in this manner. Later, I opened the atomizer valve just to see

if anything would happen. Suprisingly, the clog had removed itself

and the burner totally changed in character. The flame went from yellow

to almost blue and much less blower was required. It's a little noisy,

but the engine steams so freely now it's almost scary. Near as I can

tell, the atomizer is creating an intense local draft in the firepan through

the drilled holes, which is resulting in complete combustion even before

the gasses reach the stainless steel arch baffle. I have to close the

the draft opening a bit to maintain a neutral flame.

All Fired Up (No atomizer, just blower)

To replace the camp stove tank in actual service, I'm building a welded steel fuel tank with stays to handle the fuel under pressure; this is to be hidden inside the tender oil bunker. I gave up trying to figure out how to build a brass oil bunker that would both look good and handle pressurization. The pressure pump is to be disguised as the dipstick. The tender is to be a 73-SC-1 class whaleback tender such as the Southern Pacific used behind some of their switchers.

I'm very satisfied with the result of this experiment. The engine steams freely, is easy to fire, doesn't sting the eyes, and burns oil like its prototype.